Congratulations to The Milkhouse in Monmouth, and Tide Mill Farm in Edmunds for achieving the highest rating in The Cornucopia Institute’s latest Organic Dairy Scorecard! All the more reason to support these farms, as well as the other Maine organic dairies who are being dropped from their milk contracts…

Author Archives: Monroe Cheese Studio

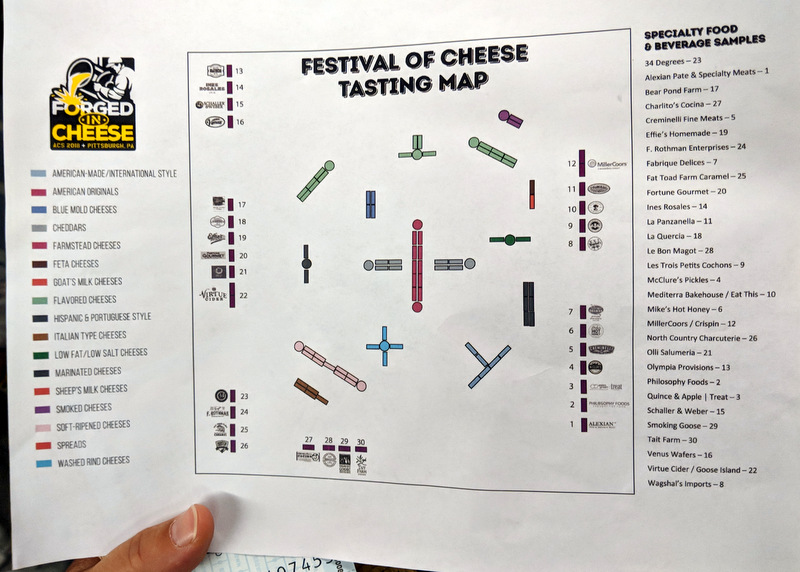

Festival of Cheese — Pittsburgh 2018

What can I say: if this isn’t the ultimate celebration of North American cheese, I don’t know what is… I think every cheese maker and cheese lover should be able to experience this at least once.

Day 3: And Away We Go

City of Bridges

Maine Rocks! (Thanks Arlene!)

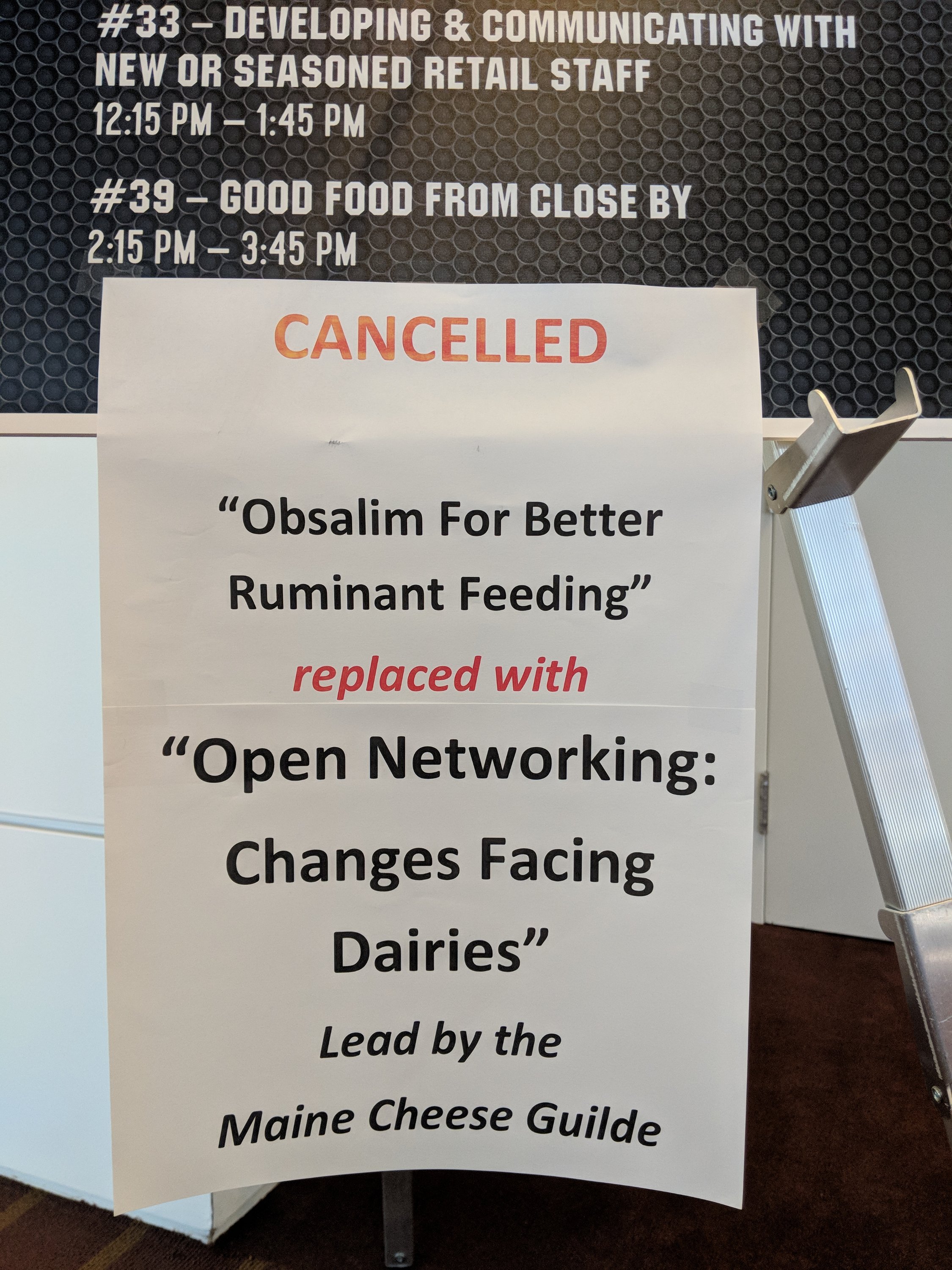

Saturday skips a breakfast meeting, and condenses the lunch break into the Brunch of Champions, so there were three different session blocks available.

First up: Cornerstone Project

Peter Dixon, Parish Hill Creamery

Rachel Fritz-Schaal, Parish Hill Creamery

Mark Gillman, Cato Corner Farm

Sue Miller, Birchrun Hill Farm

Moderator: Tom Bivens, Zephos scholar who focused on natural culture research

Earlier in the year you may have read about (or participated in) the Maine Cheese Guild’s trip to three cheese makers in Vermont at the end of February. And/or you may have read about (or attended) the Saturday session at the Denver ACS in 2017 where Peter and Rachel Fritz-Schaal described their experience working with natural cultures and then *touched on* the existence of the new Cornerstone Project. And/or you may have taken the workshop with Peter Dixon at Pineland Farms Creamery in 2015 that focused on creating and maintaining your own cultures.

And/or you may have found yourself in a bar in Lebannon, CT after the ACS Conference had concluded in 2015 sipping on a frosty pint of local brew when you overhear a conversation near you featuring a couple of cheese makers, one of whom wore a t-shirt and Carharts and a head full of red hair and a wild beard who was doing most of the talking about Albania and Macedonia and village cheeses being made with the evening milking that ripened overnight then the morning milking added in and it always resulted in cheese at the end, mostly good, sometimes fantastic, and sometimes challenging to get past the nose to the mouth. He then segued to talking about The Fabrication of Farmstead Goat Cheese by Jean-Claude Le Jaouen who says “remember this well: farmstead cheeses are always made from raw milk, they are the true product of the land.” The book describes the history of the cheesemaking process and the evolution of French goat cheeses which often depend on the local starter cultures because commercial cultures have only existed for the past 100 years or so. At which point he needs to deliniate the various traditional methods of creating starter cultures before mail-order:

- Back Slop: when a portion of the whey from today’s cheese batch is held-over to inoculate the next day’s milk at the beginning of the day (excellent for lactic set cheeses, favoring mesophilic lactic bacteria, also would have been used in early American cheese factories that were making cheddar every day);

- Pied de Cuve: similar to the Albanian method where the cheese vat stores the evening milk AND inoculates that milk for ripening overnight;

- “Italian Process”: incubate the whey at 110°F overnight to select for thermophilic lactic bacteria;

- Caillette(sp?): similar to the Italian Process but using de-albumized whey to soak a rennet vell overnight at incubation temp to set AND inoculate the milk at the same time.

- Raw milk from a single herd (either in a Farmstead arrangement, or buying in-milk from a single herd;

- Natural starters only, derived from the same herd so that it would be a true taste of those cows and where/what they are eating when the cheese is made;

- Salt should be from the nearest possible source. Parrish Hill uses Maine Sea Salt!

- Semi-hard cooked curd that could take advantage of both mesophilic and thermophilic lactic bacteria in the natural culture;

- A light rind so that there was very little effect of mold on the cheese, which could overwhelm the taste of the milk;

- Sold at an indeterminate age — this would be left to the cheesemaker;

- Aged on LOCAL wood boards, preferably from the farm itself;

- A limit on the number of “stones” each cheese maker can produce in a year. They would like to make sure that this does not become a commodity cheese available year-round from a single cheese maker selling across the US and beyond. One of the important purposes of the project is to expose cheese lovers to many different farms through their Cornerstone cheeses.

- Select the strongest and healthiest milkers in the herd;

- Handmilk them and then let that batch of milk clabber;

- If it smells and tastes like a good yogurt keep it; if not, toss it and try again;

- When you ideally have a few tasty cultures that become your “grandmothers” then you can begin making starter “mothers” out of sterilized skim milk;

- Once you have a grandmother that will reliably make a tasty mother then you have one native culture line;

- Parrish Hill is able to successfully freeze their culture grandmothers over the winter when they are not making cheese. When the spring comes and they’re ready to begin making cheese they thaw out the grandmothers and begin making new mother’s out of blanks.

- the modern Holstein

- an incredibly efficient breed for turning high-energy feed (often pre-processed) into lots and lots of milk;

- Truly a breed meant to dominate the market for fluid milk production;

- it has become a very large cow in the process (introducing health issues as a result);

- currently has a very shallow gene pool across the millions of cows in the US:

- while they represent 95% of dairy cattle in the US, there are only 31(!) unique set of genetics across all of those cows which means it’s vulnerable to a widespread disease outbreak resulting in massive disruption of the milk supply (similar to the Irish Potato Famine).

- the Welsh Black

- (quotes from the Standard Cyclopedia of Agriculture, published in the UK in 1911)

- “Welsh Black Cattle may be described as a most useful general-purpose breed, combining beef and milk-producing qualities to an extent that is exceeded by only a very few British breeds. There are breeds that grow and feed more rapidly than the Welsh; there are breeds that are better known for their milk; but there is none which combines general utility with the heartiness necessary to thrive under very favourable conditions to a greater extent thanthis breed.”

- “Welsh cows are good milkers, and the milk is generally of good quality…They are, as it is, looked upon with great favour by many dairymen, for they will thrive on very poor fare, and are generally easy to keep. It is remarkable the amount of milk a herd of Welsh cows on an ordinary hill farm will give, with practically no artificial food or turnips all through the winter.”

The fellow with the beard tells the group about previous versions of natural culture cheeses that he’s made before: Livewater Toma at Westminster Creamery, and Manchester at Consider Bardwell, and he insists that a commercial cheese using only raw milk from a single herd, and only natural cultures found in that herd was possible: a true “taste of the milk and of the maker!”

Sitting at that table with Peter in that bar were Brian Civitello of Mystic Cheese in Lebannon, CT; and Sue Miller from Birchrun Hills Farm in PA. They all had been “called to action” by John Greeley at the ACS Competition Awards Ceremony that year to “create the next American Original” cheese. “It should be a taste of what we do on our land!” Sue added. “And the more we collaborate, the better our industry.” After talking about what it could look like they hatched a plan would soon become the “Cornerstone Project.”

Cornerstone Crowd: Tom Bivens, Rachel Fritz-Schaal, Sue Miller, Mark Gillman , and Peter Dixon

The group quickly asked one more cheesemaker to come aboard to collaborate on the development of this new cheese style: Mark Gillman of Cato Corner Farm, who at first didn’t understand why he was being included on this excited and active new email chain. And pretty quickly they settled on some ground rules:

And then Rachel takes full credit for working with Robert at Fromagex and deciding that the cheese should be made in a SQUARE mold, to extend the “Cornerstone” name and to represent “the first stone that anchors the building of this new American Original!” The four cheesemakers then bought every large square mold that Fromagex had in stock at the time. The very first trial make was at Birchrun Hill using their milk and Parrish Hill Farm natural cultures in 2015. The second trial make was in February 2016 at Parrish Hill with all four participants.

The group pictures this cheese style as a US hybrid of the PDO structure that adds some flexibility: variable aging, any type of milk (cow, goat, sheep, mixed, etc.), any type of wood boards as long as their local.

Rachel explained that it might take a few more years for all four cheese makers to ‘standardize’ the Cornerstone process and to agree on all of the necessary steps that new cheesemakers will need to take in order to be allowed to market their cheese under that name. It was also clear, hearing from Mark and Sue, that it is taking a while for these cheesemakers to figure out how to fit a natural culture into their production schedule, especially since they are not currently making a natural culture cheese every day. At the same time they both expressed excitement about the success they’ve had so far working with their own natural culture, and their hope to soon incorporate that natural culture into other styles of cheese that they make, both in the mesophilic and thermophilic families.

Finally each table was given samples of three different Cornerstone Cheeses to taste: one made in March of 2018 (Birchrun Hills), February (Cato Corner), and September of 2017 (Parrish Hill). The oldest cheese was the deepest in color, slightly drier, and much more complex (naturally, since it had aged 6 months more than either of the others), but they were all very good, each with it’s own subtle complexity and thermophilic acidic tang. Even with the oldest cheese the overriding flavor was “milky” as opposed to any single dominant flavor from a ripening agent (blue, or bloomy, or smear rind). In this way I can see how each of these cheeses clearly communicate the unique combination of their pastures, their herd, and the hand of the cheesemaker. Very exciting to think of 50 or 100 different Cornerstone cheeses in the future! However, this also made it difficult to picture a “Cornerstone” category in the ACS Compeition. Because who’s to say which terroir is the “Best?” Wouldn’t that defeat the idea that every cheese simply represents the farm and the maker?

MICROBIOME

Here an outline of how Peter Dixon develops his starter cultures:

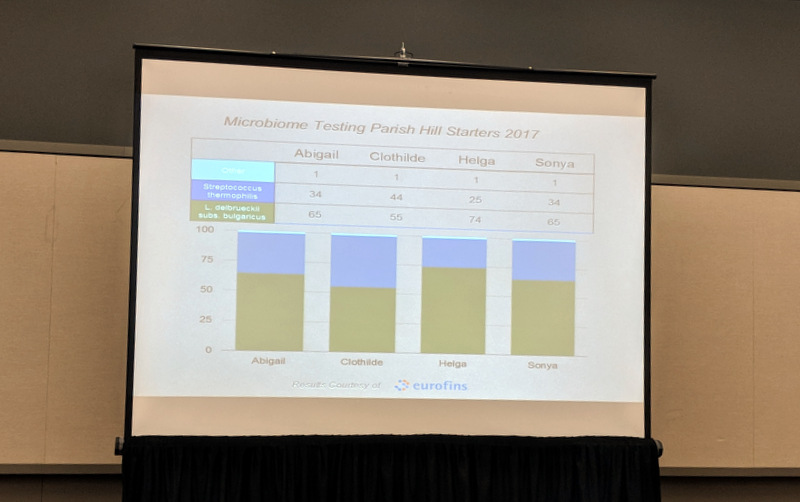

Recently a dairy science company called Eurofins offered to study Parrish Hill’s four grandmother cultures named after the cows from which they had come: Abigail, Clothilde, Helga, and Sonya. Here is what they found:

Microbiome of Parrish Hill Cornerstone starters

The analysis illustrates a typical thermophilic starter mix, which is appropriate because for Cornerstone Parrish Hill incubates their mothers at 105°F which favors only the thermophiles. You can also see that the balance of of species is different with each ‘grandmother’ which means that their cheese flavor (and probably acidification curve) would be different as well.

Building on this initial work by Eurofins, the University of Connecticut has offered to study all three farm’s natural cultures to find out what the geographic distinction of them actually is, as well as the mix of species.

After the Cornerstone Project presentation one of the questions from the audience had to do with the possibility of this Project inspiring a greater “democratization” of cheese making across the US and around the world. Sue pointed out that here in the US there are so few constraints on cheese makers to make specific styles of cheese, that the idea of using natural cultures was just another of the many “American Original” ideas that can catch on in the marketplace without a European precedent or analogy. Rachel was struck by the idea of the Project taking on a larger responsibility like “democratization” of the cheese world, though she did appreciate that using natural cultures could free some cheese makers from the expense of buying cultures. However, she also felt as though the “willingness to share” the knowledge gleaned from the development was another important component to the project, something that separated it from a typical commercial effort to develop a new cheese.

Then: The Breakfast of Champions

So Great! I got to taste the winner of the new “Boss of the Brunch” award, that is like Best in Show, but only for the breakfast type entries. This year’s winner was a ‘Herbed Rose Butter’ from Cherry Valley Dairy in Washington. It was super good, with a perfect salt balance, and the flavorings did not dominate, only help accentuate the buttery goodness.

Next up: Validation Challenges for the Makers of Unpasteurized Cheese

Bob Wills, Cedar Grove Cheese and Clock Shadow Creamery

Andy Hatch, Uplands Cheese Company

Kathleen Glass, Ph. D., University of WI-Madison

Jeremy Stephenson, Spring Brook Farms / Farms for City Kids

Bob, who is also the current chair of the ACE Foundation, felt that as we moved forward into the FSMA era of cheese making (the last deadline for compliance is this coming December), as well as beyond the idea that the 60 day rule can be considered a scientifically validated critical control point factor in making safe cheese, that cheese makers would benefit from getting additional information about how to best make raw milk cheeses.

He described the simplified flow of the cheese making process, and in the interest of time decided that they could focus only on the first two (of seven) steps: receipt of milk, and treatment of milk (before the culturing, setting and curd handling, draining, salting, and aging steps). What followed was a tutorial that focused on “alternatives to pasteurization” that could be proven to provide a “five log reduction in pathogens” the same way that pasteurization of milk is known to do.

Most of the session was turned over to Dr. Glass who initially introduced the “triangle of a Food Safety Plan that addressed pathogens: *Keep Them Out* *Keep Them From Growing* and *Kill All You Can* . She then began to dive into whether, at some point in the future, a scientific study would be able to generate a “matrix” of validated treatments that combined heat-treatment of raw milk (at lower than pasteurization temperatures), culturing, and aging, that would all combine into a specific log-reduction of pathogens. When/if such a matrix was generated (and it would need to be done by a ‘validated lab’ not simply by a cheese maker) it could give cheese makers many options for insuring that pathogen reduction was being addressed in the food safety plans. It would need to be a “matrix” of options because it depended on the possible pathogen levels found in the raw milk itself. The lower the initial levels, the lower the minimum log-reduction that would need to be applied for each recipe.

After Dr. Glass’s presentation Jeremy made a plea to the audience to continue the discussion about this topic after this conference session because “we need to communicate within our community.”

During the question section, a cheese maker justifiably asked why it seemed that Dr. Glass suggested that ALL raw milk for cheese making would need to be heat-treated to some extent? Bob replied that in the interest of the session time-frame he felt he could bring the group only one example of best practices for handling raw milk for cheese making, and this was what he chose.

Another person in the audience pointed out that with raw milk it seems like herd health is one of the most important factors. However, at the same time vet services are disappearing from more and more communities which means that it’s harder for dairy farmers to get the resources they need to maintain optimum herd health. Shouldn’t that issue be addressed in this context?

Another person offered that micro-filtration of milk might be a validated treatment of raw milk?(Micro-filtration is common in Europe where milk is pushed through a filter so fine that it removes all the microbiology, along with the cream. The cream alone is then pasteurized before being added back to the filtered milk.)

And finally: Conservation of Heritage Breeds in North America

Bronwen Percival: Neal’s Yard Dairy, UK

Jeannette Beranger: The Livestock Conservancy, NC

Sarah Bowley: SVP Foundation, RI

Dr. Mario Duchesne: Assoc. de mies en valeur des bovins de la race Canadienne dans Charlevoix

Moderator: Sam Frank, former Zephos scholar who focused on Heritage Breed research

This session is really a mash-up of the work that Sam has done on Heritage Dairy Breeds around the US and Europe, as well as the strident plea to increase the use of Heritage Breeds for cheesemaking made in the recent book by Bronwen and her husband Frances in Reinventing the Wheel.

Tasting the Farm System

Bronwen spoke first by providing an overview of what a heritage breed is and why it can be so important for the future of making complex cheeses that truly capture the Taste of Place. To whit:

Ultimately cheese is made up from the combination of the LAND, the ANIMALS on that land and what they eat, and then the MICROBES found around that land, in the milk, and that the cheesemaker chooses to add. “Cheese allows milk to express its inner character with much more fluency than when it’s consumed as a fresh liquid.”

This circles back to the breed of cow from which one sources the milk that is used to make cheese because when you have a Holstein in Maine it will need to be fed many of the same foods from the same processed sources as a Holstein in Pennsylvania or California. Where as if you had a herd of Welsh Black they could get much or all of its nutrition by grazing on the local plant matter, ideally those plants living on terrain on which it’s generally impossible to grow anything else. Though you probably get less milk from a Welsh Black than from a Holstein you will pay less to feed a Welsh Black (assuming you own sufficient grazing lands) and their milk will more closely reflect your Taste of Place.

However, as a cautionary tale as well as an introduction to the next three speakers, Bronwen’s last slide was a picture of a Sheeted Somerset cow, which had been the primary cattle breed used to make Cheddars in the 19th century until the Holsteins and Jerseys showed up and the breed became extinct. On top of the picture it read: “Genetic Variation is a key to adapting to different definitions of perfection.”

The Livestock Conservancy

(formally the American Livestock Breeds Conservancy)

So what can we do? Well, Jeannette Beranger from the Livestock Conservancy spoke about the work they do to actually conserve rare and endangered breeds of cattle, pigs, goats, sheep, donkeys, horses, rabbits, and poultry. Most of the work is to coordinate farmers who are committed to raising a few of at least one heritage breed, and help the larger community of different farmers focused on each breed coordinate sharing genetics, keeping lines clean but genetically diverse. Because for livestock breeds to “survive” then many different examples of that breed must live somewhere, and reproduce in a way that maintains the breed characteristics as well as its genetic strength.

Jeannette also made the point that although some breeds may be thriving, that in some way the genetics have changed so much over the last 100 years of “improvement” that one might even consider the “heritage Holstein” a different breed than the modern Holstein. (This same pronounced breed transformation has taken place in Jersey and Guernsey breeds as well.)

While the work of the Livestock Conservancy is to literally keep breeds *alive*, the SVF Foundation (whose grounds originally included the “Surprise Valley Farm” in Newport, RI) has taken another tack: to maintain a bank of genetic information on as many breeds as possible, so that if a breed suffers a population disaster or cannot be sustainably grown and maintained on farms, that there will still be enough saved (frozen in liquid nitrogen) germplasm (in the form of eggs, sperm, and oocytes) that the breed, and it’s genetics, could be resurrected in the future. Their goal is to maintain 200 embryos and 3,000 straws of semen for every breed.

The Story of One Endangered Breed: the Canadienne cattle

Dr. Mario Duchesne explained about the work that he and others do at the Association for the Development of Canadienne Cattle (Association de mise en valeur des bovins de race canadienne dans Charlevoix). Apparently this breed did not start out as such, but began as an amalgam of cattle imported from the Norman and Brittany coast in France, and thus included the first cows brought to the Charlevoix area of what would become Quebec. However since that 1609 settlement the bulk of these formerly French cows (likely including several of the French breeds at the time) were bred and adapted to the conditions in Canada that they coalesced into a recognizable breed that does not exist in France currently. They are particularly well suited to the harsh climates they faced in Canada and in 1850 there were close to 300,000 of them in Canada. However, in the late 1800s the “British Breeds” of Ayershire, Holstein, Jersey, and Brown Swiss arrived and displaced the Canadienne. In 1890 there were 100,000 Canadienne, by 1950s that had been cut in half, by the 1980s a tenth, and then by 2010 there were only 300 of them identified in all of Canada. However, with those 300 remaining cattle Dr. Duchesne pointed out that the remaining Canadienne herd still has more genetic diversity than all the Holsteins in Canada!

Dr. Duchesne’s team’s goal is to maintain and build a network of farms who are committed to the Canadienne breed and therefore resurrect the breed’s population, as well as rid it of unusual traits such as weak milk persistence during pregnancy. Currently those farms who are milking Canadiennes are allowed to use a new DOP label, ‘Le 1608″, when marketing products made from the breed.

At the end of the presentation there was a lively discussion sparked when one audience member asked the breed conservators: what is a “breed” exactly? That full discussion/debate will have to wait for another ACS Conference to fully be resolved.

For me it was on to meet my aunt and uncle on “The Strip” for a frosty cold local beer. They had driven up from West Virginia and would later join me and Alison at the ultimate finale: The Festival of Cheese!